Rotors of rotating machines, including gas turbines, are extremely sensitive to misalignment. Regular maintenance and laser alignment during commissioning can significantly reduce regular maintenance costs in the long term.

For access to the compressor rotor and compressor blades, as well as bearing units, it is necessary to remove GTU casings. Before their removal, GTU structure should be properly supported by means of mechanical jacks to avoid case twisting.

Overhaul includes complete inspection of hot gas path with replacement of all necessary units: working vanes, nozzle apparatus, combustion chamber elements and fuel system.

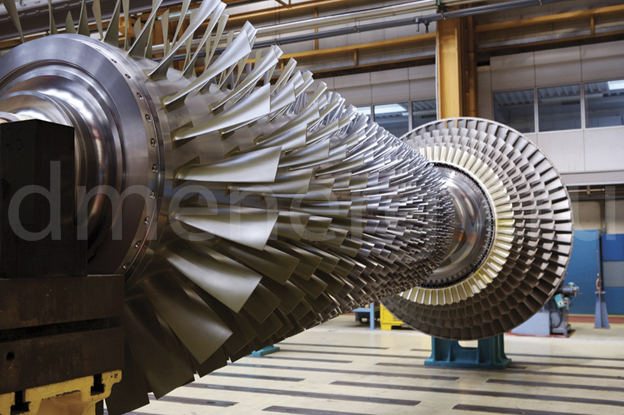

During overhaul, the compressor assembly is thoroughly inspected. The compressor inlet is checked for erosion, corrosion and mechanical damage. The rotor is also checked for cracks and other damage, bearing shells for wear.

The turbine is assembled in reverse order, after which the gas turbine, generator and auxiliary equipment are laser aligned.