General Information about the GE LM2500 Turbine

The General Electric LM2500 is an efficient two-shaft simple-cycle gas turbine. It is based on the GE TF39 and CF6-6 aircraft engines.

The LM2500 is the most “experienced” high-efficiency gas turbine in the 22 to 33 MW power class. Currently, around 2,100 units have been shipped and are operating in various locations around the world. The total operational time of LM2500 turbines exceeds 75 million hours. The LM2500 has been one of the best-selling gas turbines for over 40 years and maintains a reputation as the most reliable industrial gas turbine generator in its class. The LM2500 turbine family continues to evolve to provide increased value to customers.

Simple to install and maintain, the GE LM2500 gas turbine offers high thermal efficiency, along with low fuel and air consumption.

Model range

|

|

|

| LM2500 DLE | LM2500+ DLE | LM2500+G4 DLE |

Comparison of General Electric LM2500 Models Key Performance Indicators

| Parameter | Units of Measurement |

LM2500 DLE

|

LM2500+ DLE

|

LM2500+G4 DLE

|

| Power (ISO) | MW |

22,4

|

31,1

|

33,4

|

| Heat Rate, Gross (LHV*) | kJ/kW·h |

10156

|

9674

|

9671

|

| Efficiency, Gross (LHV*) | % |

35,4

|

37,2

|

37,2

|

| Exhaust Mass Flow | kg/s |

67,58

|

41,28

|

96,62

|

| Exhaust Temperature | °C |

547

|

539

|

552

|

*LHV: Lower Heating Value.

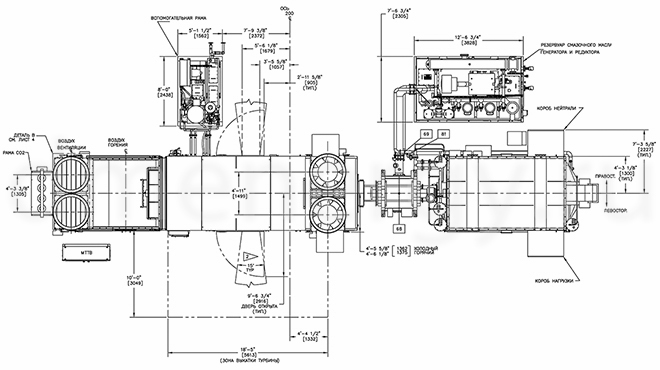

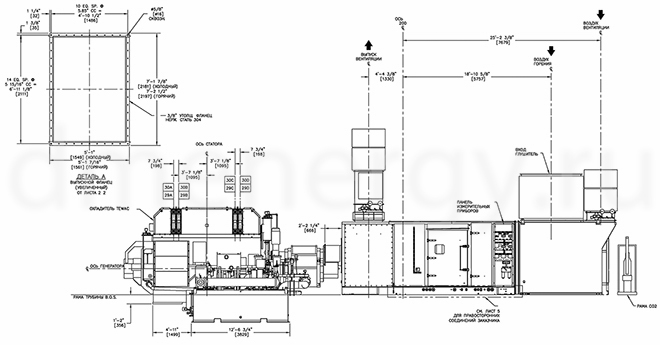

Application

The GE LM2500 family of gas turbines is ideal for onshore and offshore mechanical drive, plant power generation, pipelines, oil and gas platforms, cogeneration and combined cycle applications.

The General Electric LM2500 turbine is also referred to as an offshore turbine. It fully meets current and future regulations for offshore applications, as well as providing superior availability for a variety of military applications including patrol boats, corvettes, frigates, destroyers, landing craft and aircraft carriers.

Features

- Efficient solution for oil and gas and industrial needs.

- Quick installation and easy maintenance due to minimal size, weight and space required.

- Robust construction (over 99%); availability (over 98%).

- Proven ability to achieve fast start-up (<10 minutes) and operate in highly cyclic conditions.

- Dual fuel solution: distillate and natural gas.

- Capable of utilizing crude oil, propane, coke oven gas, ethanol and LNG.

- Reduced NOx (<15 ppm) with DLE combustion chamber; steam or water injection systems are also available to limit NOx emissions.

Model LM2500+: more power with the same proven reliability

Model LM2500+: more power with the same proven reliability

- Another compression stage for an additional 8 MW of simple cycle output.

- One-piece “monolithic disk” first stage (vane+disk) for increased durability.

- Improved fit for piping, maximum output and combined heat and power generation.

LM2500+G4: the highest efficiency in the LM2500 family

- Modified first stage for increased airflow and pressure coefficient..

- Improved compressor and turbine section design and materials for greater performance.

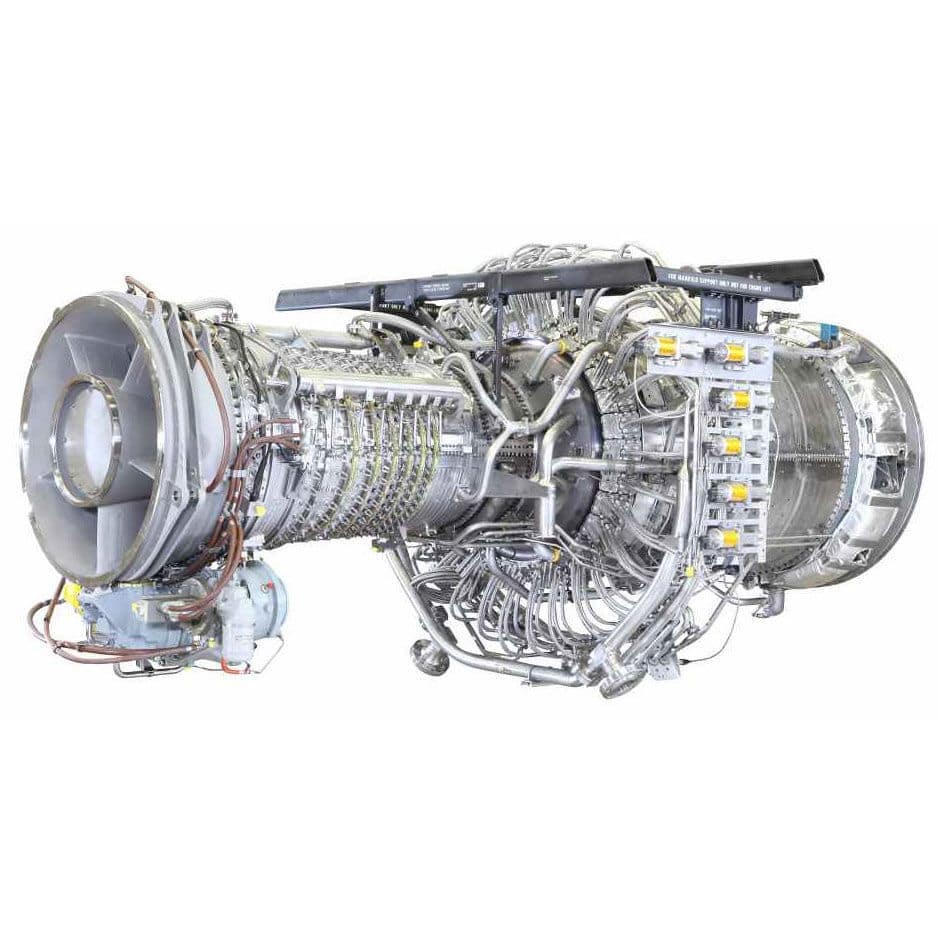

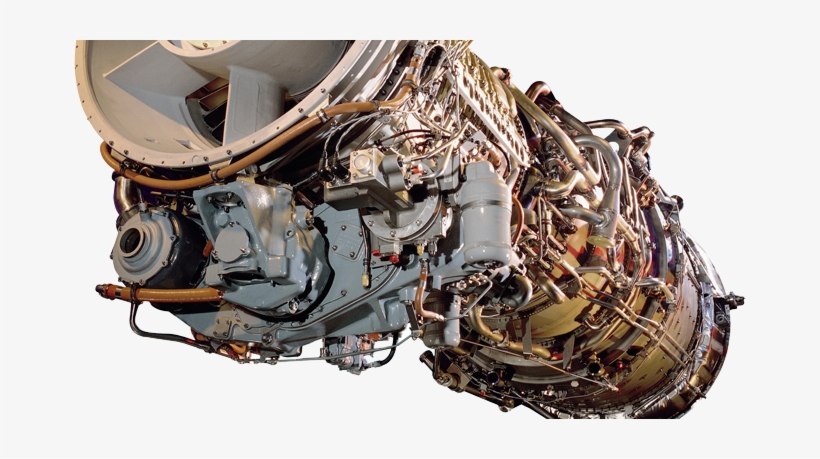

GE LM2500 turbine design

The GE LM2500 includes four major components:

- A sixteen-stage compressor (18:1 pressure ratio) with seven stages of rotary stator vanes and inlet guide vanes;

- fully annular combustion chamber with externally mounted fuel injectors;

- a two-stage air-cooled high-pressure turbine, which drives the compressor and an additional gearbox;

- a six-stage aerodynamically coupled low-pressure (3600 rpm) power turbine driven by a high-energy flow of generator exhaust gas.

The LM2500 includes a gas generator, power turbine, fuel and oil pump, fuel management system and speed control system, intake and exhaust sections, cleaning system, controls and engine starting and monitoring devices.

CEM GmbH supplies spare parts and provides maintenance and repair services for GE LM2500 turbines.