- General information about GE Frame 5 turbines

- MS5001 Turbines

- MS5002 Twin-Shaft Turbine

- Construction

- Gas Turbine Blades

- Offers for GE Frame 5 Turbines

General information about GE Frame 5 turbines

The General Electric Frame 5 is considered an iconic high power gas turbine. It has unquestionably stood the test of time.

Since 1957, more than 3,000 Frame 5 units have been built and shipped in both single-shaft (MS5001) and twin-shaft (MS5002) versions for power generation (50 and 60 Hz) and mechanical drive applications. The turbines of this series operate in simple and combined cycle. They are installed both onshore and offshore (oil rigs, barges) and can be equipped with a single or dual fuel combustion system.

GTK-25IR gas pumping units with GE Frame 5 turbine are in operation in Russia..

GTK-25IR gas pumping units with GE Frame 5 turbine are in operation in Russia..

MS5001 turbines

The first single-shaft MS5001 turbine was delivered from the plant in Schenectady (USA, New York State) more than 58 years ago. The MS5001 is still in production today, with parameters almost 2.5 times higher than those of earlier models (see files below).

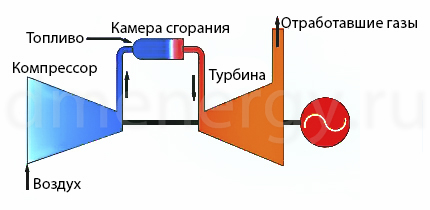

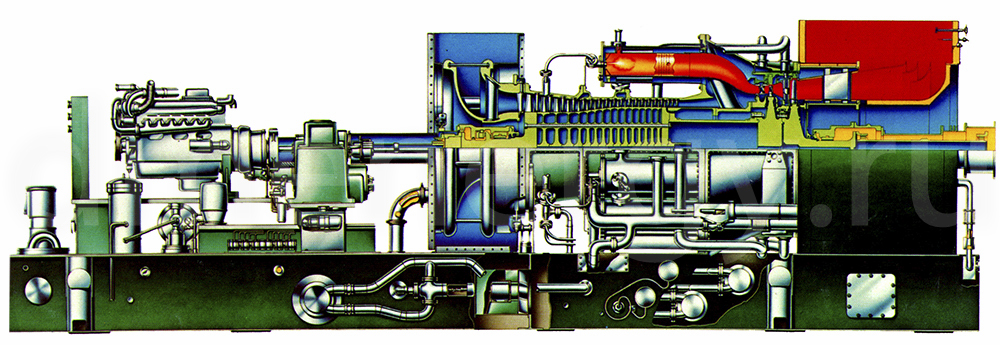

Schematic diagram of MS5001 single-shaft turbine operation

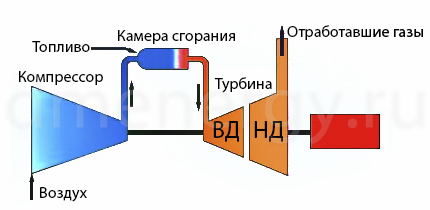

Double-shaft turbine MS5002

A twin-shaft version of the Frame 5, the MS5002, first produced in the 1970s, was designed specifically for mechanical drive applications, most commonly for large mainline compressors and pumps. This turbine is sometimes used in electric generating plants.

A twin-shaft version of the Frame 5, the MS5002, first produced in the 1970s, was designed specifically for mechanical drive applications, most commonly for large mainline compressors and pumps. This turbine is sometimes used in electric generating plants.

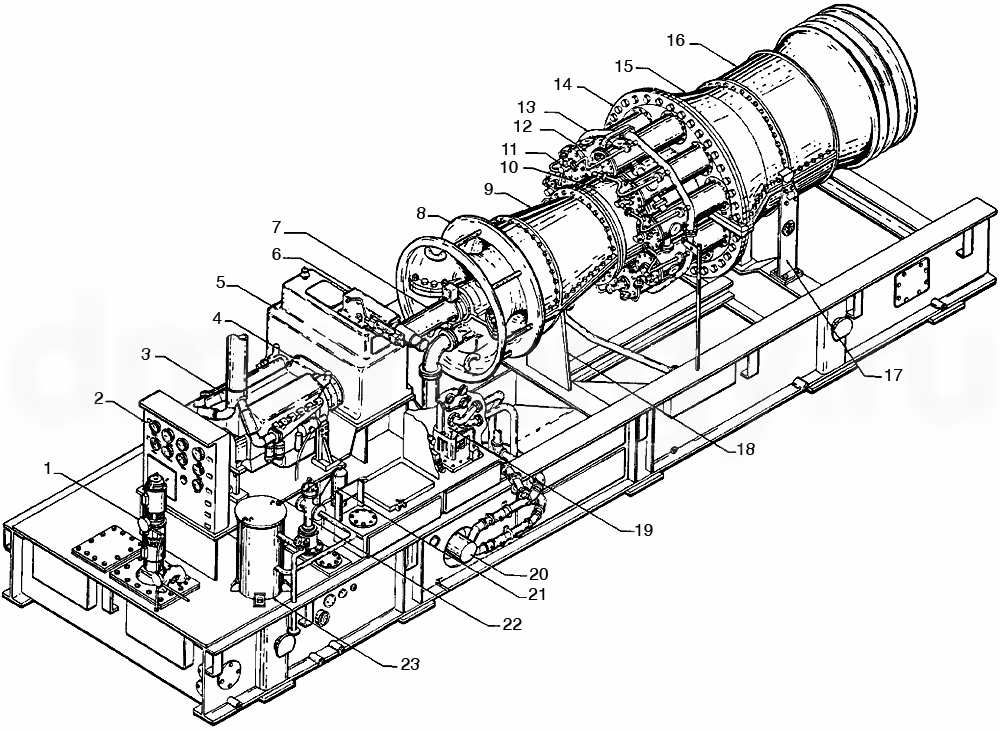

Schematic diagram of the MS5002 twin-shaft turbine

There are five MS5002 models in operation worldwide today: A, B, C, D and E. All of them can be equipped to burn various types of gaseous and liquid fuels. The simple and robust design allows for on-site maintenance without specialized tools or auxiliary workshops.

The MS5002E turbine is the latest addition to the Frame 5 turbine family and has been developed in response to increased customer demand for a gas turbine in the 32MW power range that is highly efficient, affordable and has a low environmental impact.

To ensure high reliability and availability, the MSS002E has a low combustion temperature compared to many modern turbines. High efficiency is achieved by using advanced design tools to optimize aerodynamic surfaces, clearances, leakage and cooling flow distribution. The MS5002E turbine’s NOx level is less than 15 parts per million due to the use of a low dry gas emission combustion system based on GE DLN2 combustion technology.

The MS5002E has successfully completed an extensive test program.

More information about the MS5002E GTU>>

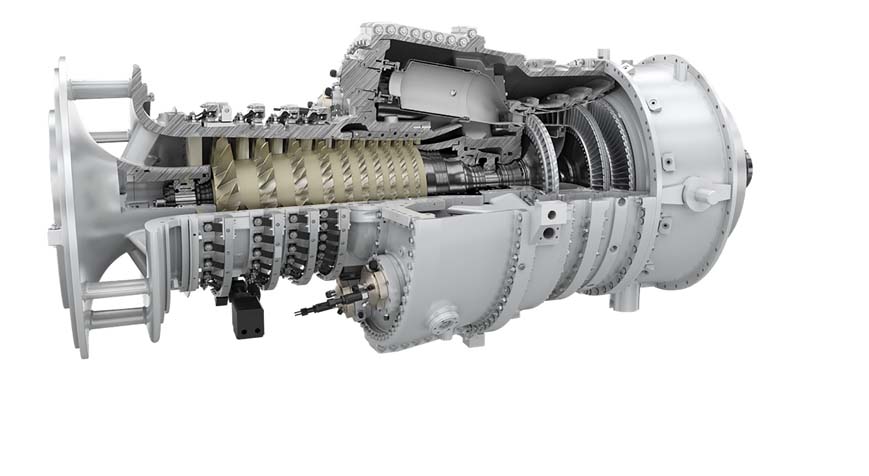

Construction

The MS5001 turbine construction was designed to be as simple as possible for reliability and durability, with a low pressure ratio, low combustion temperature, only two uncooled turbine stages and a dimensionally stable casing.

The main construction elements of the Frame 5 single-shaft turbine are:

- Two-stage turbine;

- 17-stage axial compressor;

- combustion system with ten chambers.

- – auxiliary and emergency lube oil pump

- – control panel

- – starting aids

- – torque converter

- – auxiliary gearbox

- – hydraulic ratchet mechanism

- – auxiliary clutch and safety device

- – air intake housing and NQI bearings (assembly)

- – compressor housing front

- – rear part of the compressor housing

- – fuel injector

- – combustion chamber

- – fuel gas line

- – compressor discharge housing

- – turbine casing (assembly)

- – exhaust frame (assembly)

- – rear engine mount

- – front engine mount

- – turbine overspeed shutdown valve and control valve

- – lubrication system heat exchanger

- – oil filter

- – liquid fuel shut-off valve

- – liquid fuel filter

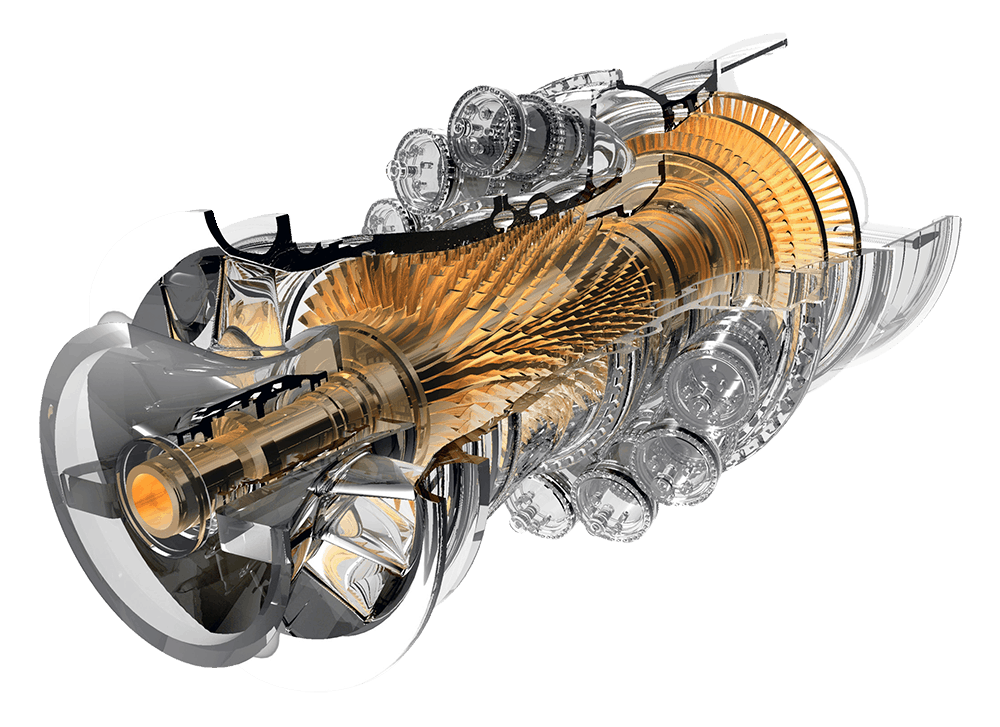

Gas turbine blades for GE Frame 5 turbines

Gas turbine blades, or as they are often called “blades”, are parts designed to ensure the rotational process of the rotor of a GE Frame 5 gas turbine. There are several stages of blades

MS 5001 first stage gas turbine bladesBasic information Blade Specifications Hardware Installation

|

MS 5001 second stage gas turbine bladesBasic information Blade Specifications Hardware Installation

|

MS 5001 first stage gas turbine bladesBasic information Blade Specifications Hardware Installation

|

Газотурбинные лопатки MS 5002 второй ступениBasic information Blade Specifications Hardware Installation

|

MS 5002 first stage gas turbine deflectorBasic information Blade Specifications

|

MS 5002 second stage gas turbine deflectorBasic information Blade Specifications

|

Offers for GE Frame 5 turbines

CEM GmbH offers a complete range of spare parts and services for Frame 5 industrial gas turbines. All structural elements can be replaced, upgraded or modified.

Today’s advances in gas turbine technology are highly applicable to the GE Frame 5 series turbines. The judicious use of advanced equipment and control systems can increase power output, reduce NOx and CO emissions, improve efficiency, extend inspection intervals, improve reliability and operability, and modify exhaust and exhaust gas temperatures.

It is possible to repair and/or upgrade the turbine to a performance that significantly exceeds that of the plant at the time of initial installation.