KLEVERS ITALIANA is one of the leading companies in the research, development and production of thermal and acoustic insulation. Founded in 1984, it operates worldwide with large international customers distributed in different market segments.The main customers in the gas turbine segment are:

- Ansaldo Energia S.p.A.

- General Electric

- Siemens

- Solar Turbine

- as well as domestic gas turbine plants

KLEVERS ITALIANA offers its assistance throughout the entire life cycle of the insulation for gas and steam turbines, from the design stage to field operation, in full cooperation with the OEM companies. KLEVERS ITALIANA is Ansaldo Energia’s contractor for the supply of new insulation on GT 94.2 A, 94.3 A, 64.3 A GTUs, including the Alstom GT 26.

Our teams of Supervisors, expert installers and skilled workers based in our Naples facility are trained to find solutions anywhere in the world and to carry out the initial assembly, supply or maintenance of the insulation, with the possibility of providing spare parts for replacement within a few days or, in case of non-standard situations, to carry out the work on site. KLEVERS ITALIANA has been supplying and installing isolation kits for gas turbines since 1991. The best experienced models are the GT AE 94.3A, GT AE 94.2A and GT AE 64.3.

KLEVERS ITALIANA has achieved the following achievements during the entire existence of KLEVERS ITALIANA:

- Manufactured and installed more than 140 insulation blocks for the GT

- About 100 insulation blocks for steam turbine manufactured and installed

- A recent turnkey project was realized based on the GT model AE 94.2 A

- Product upgrade completed on the GT AE 94.3 A model, in the diffuser area.

- Design, fabrication and assembly of insulation for GT AE 94.3 A, 320 MW capacity.

- Design, fabrication and assembly of “reinforced” acoustic insulation for GE ST.

- Continued design development for GT36

- Research, design and development of internal insulation for the Kompaflex GT AE 94.3 A cone. Es

Procedure for turnkey projects

KLEVERS ITALIANA can develop a complete insulation project, from design, development, fabrication and site installation.

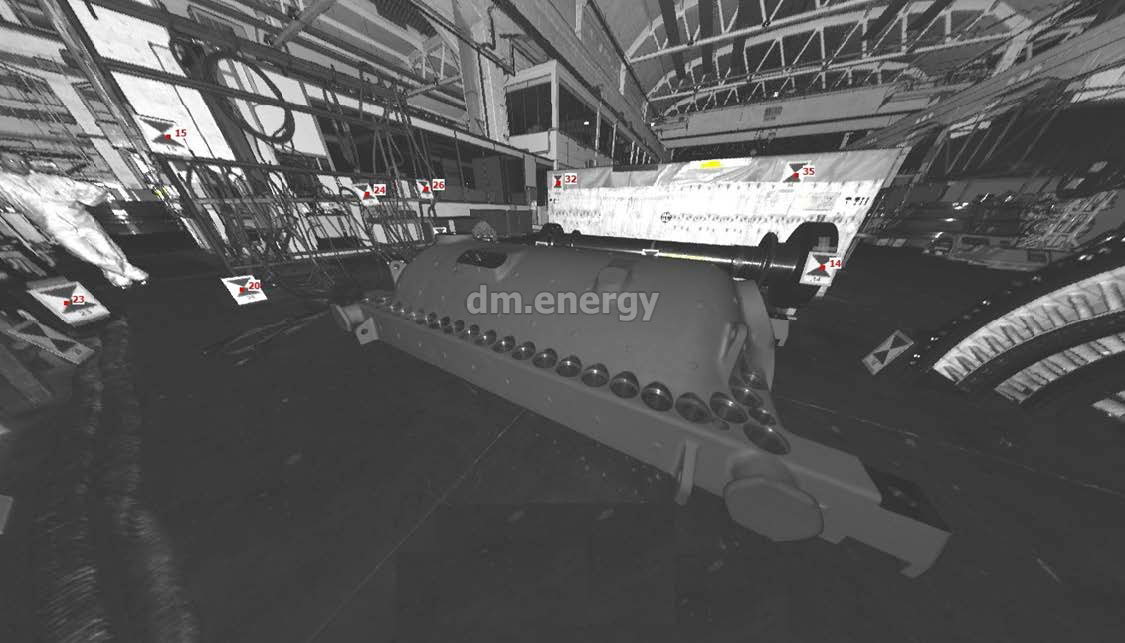

REVERSE ENGINEERING WITH 3D SCANNER

In cases where a 3D model of the insulation equipment is not available, an on-site inspection is performed with our 3D scanner.

CAD / CAM PROCESS

Each product is studied and researched by a team of engineers who, after developing spreadsheets using CAD and CAE processes, lead to the creation of drawings, execution diagrams and information data that, through CAD-CAM integration, drive machines and work teams to produce products, both for in-line production and for production based on individual projects.

KLEVERS ITALIANA has developed a new project for the efficient internal insulation of the transition cone of the GT AE 94.3. series, including the following steps:

- material research

- thermal calculations

- optimal design

- sample size testing

The company CEM GmbH is ready to undertake the realization of projects on heat and vibration insulation of gas turbine plants of the following manufacturers:

- Ansaldo Energia S.p.A.

- General Electric

- Siemens

- Solar Turbine

- as well as domestic gas turbine units