Gas collectors of the combustion chamber

A gas turbine consists of several components – turbine , compressor and combustion chamber.The compressor compresses the air and feeds it into the combustion chamber, where the air vibrates with fuel and burns. The flow of the hottest gases passes through a downward path to the turbine section. In the turbine, the process expands. The flow of gas sets it in motion. The turbine, located on the same shaft as the compressor, in turn drives the compressor.

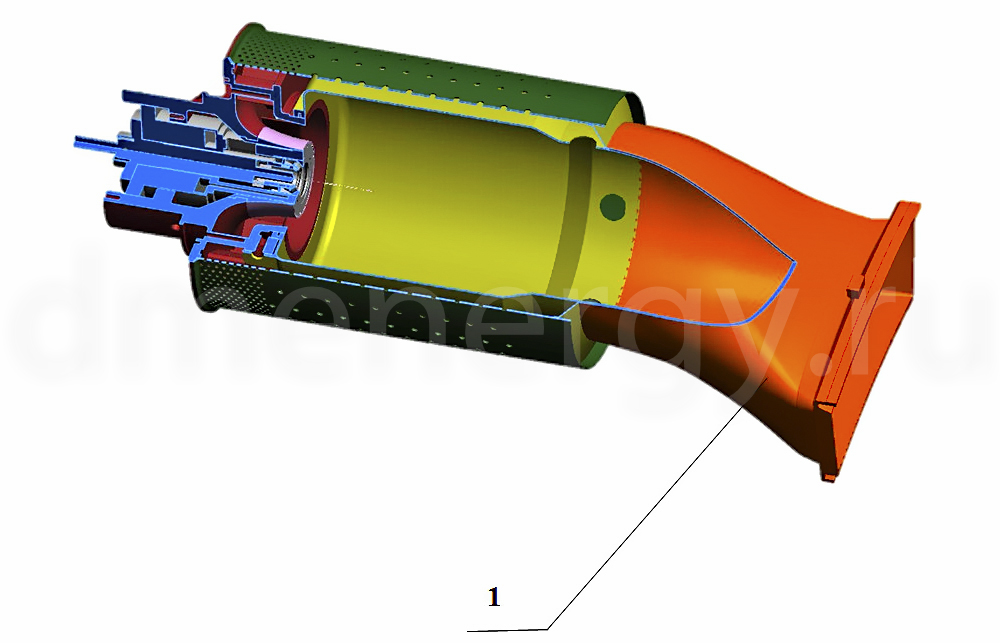

The gas collector (flow sleeve, adapter) ( 1 ) directs the combustion gases from the flame tube downstream to the nozzle device of the first stage.

The external gas collector is mounted on covers with perforated holes. Air is supplied into the openings, which serves to cool the air.

A gas collector connected to other transmission sources of a hot gas turbine gas plant operates under high temperature conditions. The metal generates significant thermal stresses. It is very important that the material permits operation under these conditions with the stated service life. For this reason, the gas collectors have a thermal barrier protective coating, as do the other components in the direct path.