One of the main challenges for the energy sector is to improve the efficiency of natural gas utilization as a power fuel. Currently, most natural gas is burned in steam power units. In Russia their efficiency is 40…42%. An alternative to steam power units is combined cycle gas turbines (CCGT). Steam-gas plants, first of all, of utilization type (CCGT-U), in comparison with steam power units, have significant economic, investment, environmental and other advantages. They occupy an increasing place in the power industry and power engineering of many countries. CCGT is a very efficient, in terms of efficiency, power generation system. Due to utilization of heat of outgoing high-temperature gases of GTU it is possible to obtain much higher cycle efficiency.

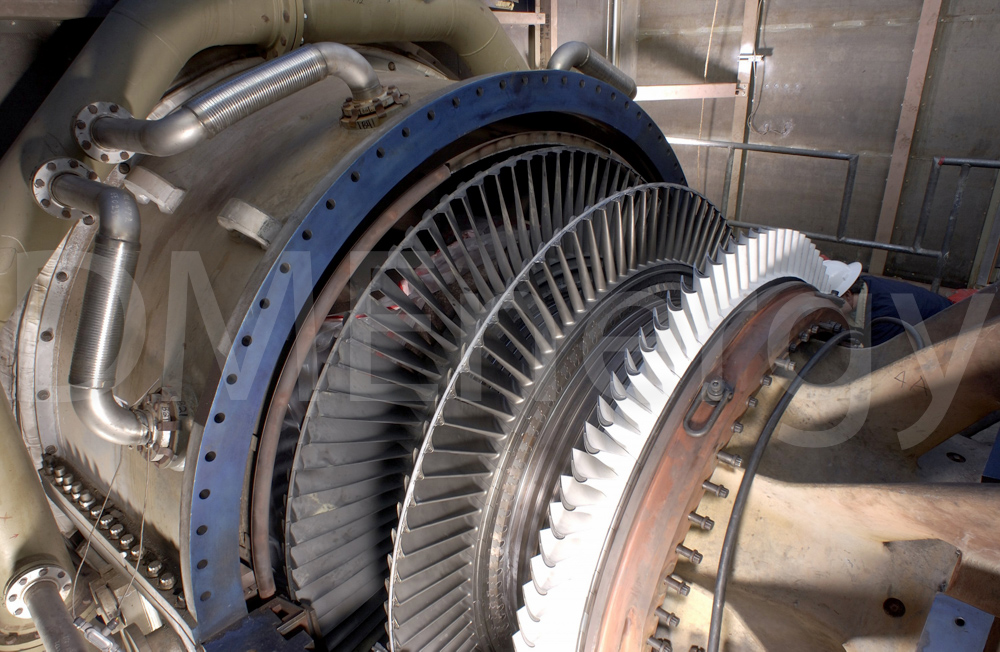

Reliability and economic efficiency of CCGT-Us are first of all expedient of GTU operation, and their efficiency. When designing CCGT-Us, special attention is paid to the design of CWs.

The main incentive of modern CW development is the desire to reduce harmful emissions. In accordance with other technical solutions in stationary GTU CWs are used dilution (injection) of water or steam, flame temperature and, as it is considered, emissions. In spite of efficiency, this economical thermodynamic mode of efficiency prevents CO afterburning and causes corrosion of turbine parts . On the contrary, water or steam injection is not used in CW combustion of «poor» PP fuel assemblies, so they are often referred to as Dry Low Emissions DLE combustion chambers (DLE).

The combustion chamber (CC) is primarily responsible for the level of harmful emissions into the atmosphere, the low level of which is a mandatory requirement for the introduction of modern facilities in the territory. Power plant charges for harmful emissions are increasing annually, so the development of low-emission CWs is becoming an increasingly important issue.

The second main parameter determining the CS is GTU efficiency. Particularly strongly influences the influence of the design of the CC on the efficiency at low loads. To maintain a high level of SGCPTU at low loads, it is necessary to ensure the completeness of fuel burnout.

Often ensuring high completeness of fuel combustion and low level of pollutant emissions leads to contradictions in CW designs. Therefore, the search for a compromise design solution for CW is the most difficult group, the solution of which is necessary to achieve high technical and economic performance of CCPP as a whole.